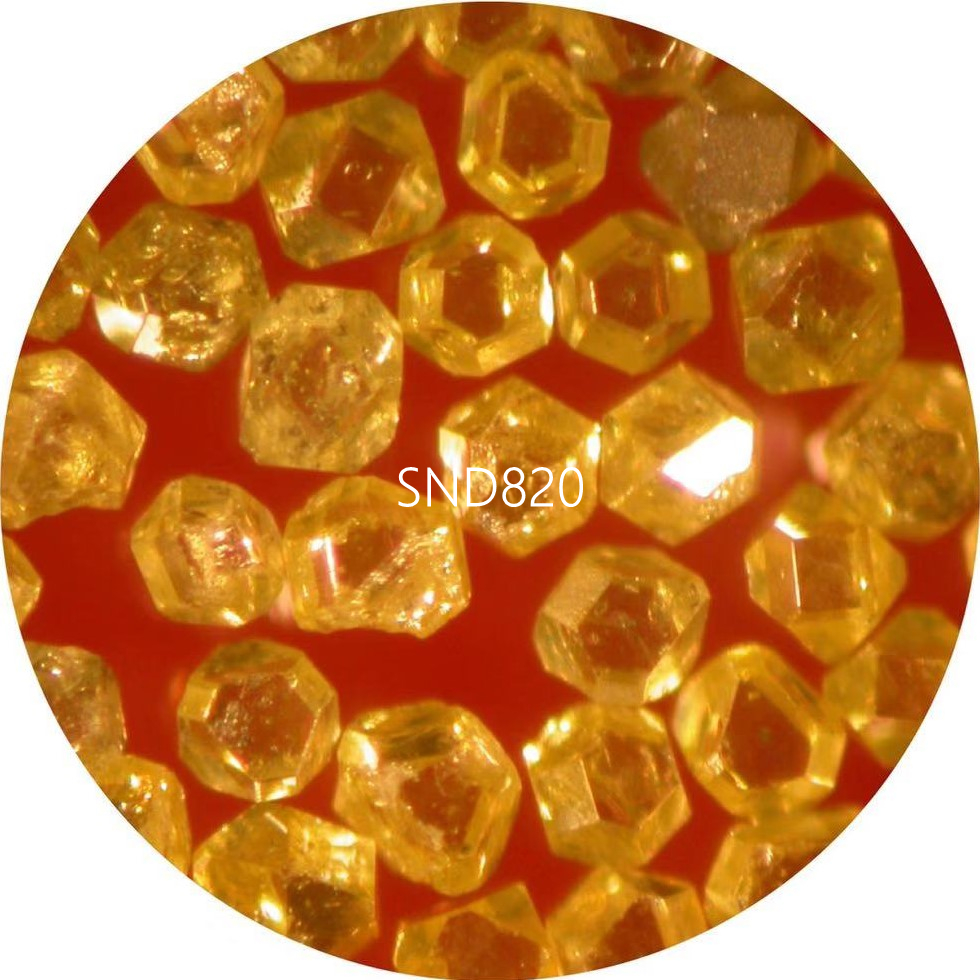

SND-M10 Synthetic Micron Dheeman Powder Polishing Abrasive for General Purpose

SND-M10 Synthetic Micron Dheeman Powder Polishing Abrasive for General Purpose

1. Micron Diamond Powder Hordhac

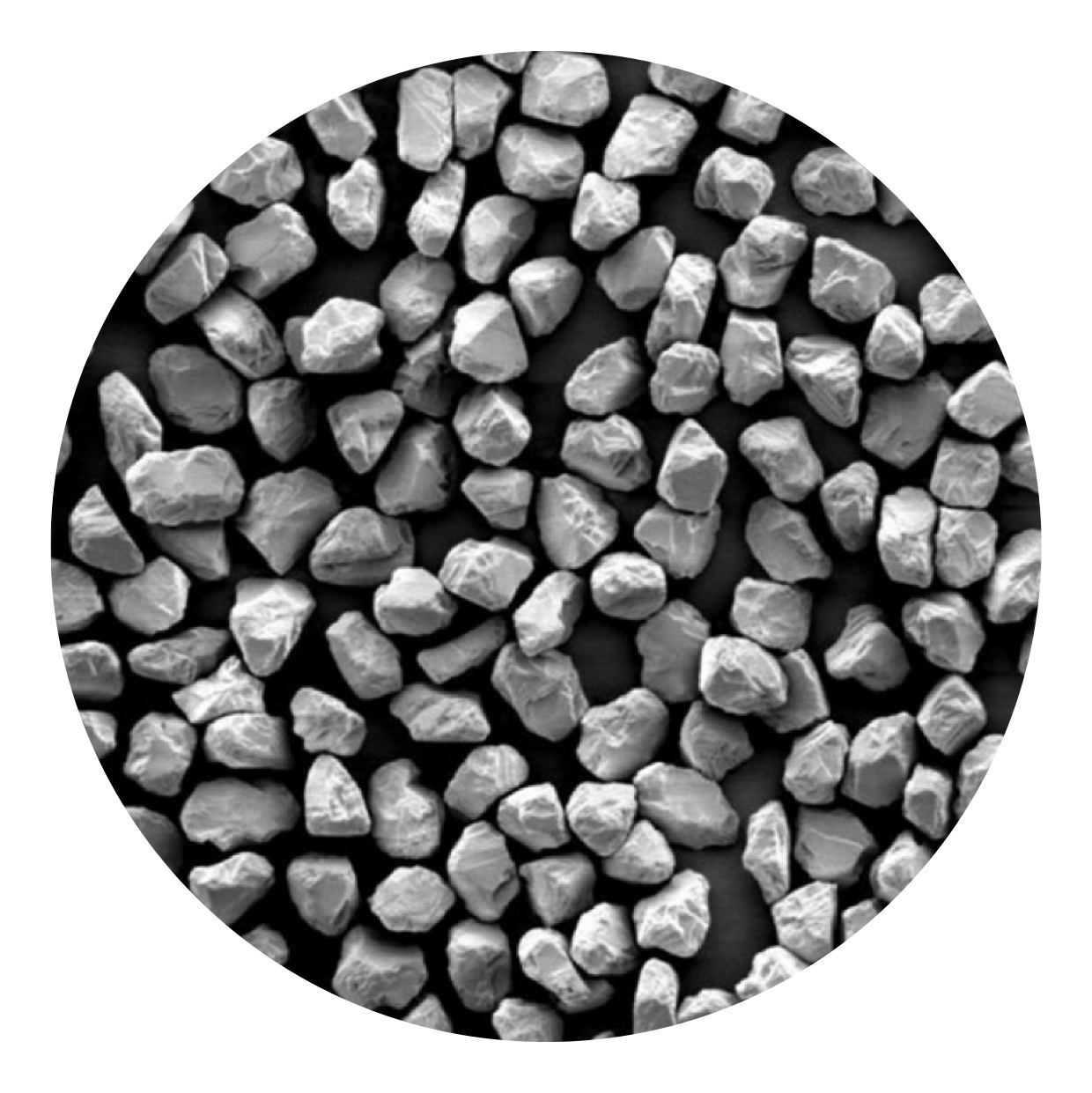

SND-M10 waa ujeedo guud oo ah budo dheeman micron ah oo leh qaab crystal aan joogto ahayn oo lehxoogaa xoog lehqaybinta cabbirka,content wasakh hoose.Sarehufnaan.Waxaa loo isticmaali karaa gudahaxabagta,

vitrified, bond birahaiyo alaabta korantada.

2. Cadaynta budada dheemanka Micron

|  |  |

| SND-M05 0-0.125~40-60 | SND-M10 0-0.125~40-60 | SND-M15 0-0.125~40-60 |

| Qaab crystal aan joogto ahayn, nuxurka wasakhda ah iyo qayb qaybinta cabbirka, waa la isticmaali karaa oo ku jira resin iyo vitrified bond. Ku habboon waxtar sare leh shiidi iyo turxaan bixin codsiyada, sida dhagaxyada, tiles, Jade & jawharad, iwm. | Qaab crystal aan joogto ahayn oo leh xoogaa xoog leh qaybinta cabbirka, content wasakh hoose.Sare hufnaan.Waxaa loo isticmaali karaa gudaha resin, vitrified, bond biraha iyo alaabta korantada. | Block hadhuudh, ilaa xad cabbirka walxaha xoogga leh qaybinta, wasakhda yaryar, hydrophilic wanaagsan waxqabadka.Ku haboon wax badan oo looga baahan yahay, polishing, waxaa loo isticmaali karaa PCD dheeman tayo sare leh koollada iyo slurry iyo kuwa kale alaab dheeman tayo sare leh. |

3. Dheeman Micron ah oo la heli karo Cabirka grit

| Heerka Caalamiga ah | Heerka Shiinaha | Cabirka mesh | Codsiga |

| 0-0.1 | W0.1 | 100000 | Dabaysha Super Mirror |

| 0.0.25 | W0.25 | 60000 | Dabaysha Super Mirror |

| 0-0.5 | W0.5 | 30000 | Dhalashada muraayada |

| 0-1 | W1 | 15000 | Dhalashada muraayada |

| 0-2 | W1.5- | 13000 | Daalid Fiican |

| 1-2 | W1.5 | 12000 | Daalid Fiican |

| 1-3 | W2.5 | 10000 | Daalid Fiican |

| 2-4 | W3.5 | 6500 | Daalid Fiican |

| 2-5 | W4 | 5000 | Daalid Fiican |

| 3-6 | W5 | 4000 | Daalid Fiican |

| 4-6 | W6 | 3500 | Daalid Fiican |

| 4-8 | W7 | 3000 | Toosinta caadiga ah |

| 4-9 | W10 | 2500 | Toosinta caadiga ah |

| 5-10 | W10 | 2000 | Toosinta caadiga ah |

| 6-12 | W10 | 1800 | Toosinta caadiga ah |

| 8-12 | W12 | 1600 | Toosinta caadiga ah |

| 7-14 | W14 | 1500 | Toosinta caadiga ah |

| 8-16 | W14 | 1300 | Toosinta caadiga ah |

| 10-20 | W20- | 1200 | Toosinta caadiga ah |

| 12-22 | W20 | 1000 | Toosinta caadiga ah |

| 15-25 | W20+ | 800 | Toosinta caadiga ah |

| 20-30 | W28 | 700 | Toosinta caadiga ah |

| 22-36 | W28+ | 600 | Shiidi qallafsan |

| 20-40 | W40- | 500 | Shiidi qallafsan |

| 30-40 | W40 | 450 | Shiidi qallafsan |

| 35-45 | W40+ | 400 | Shiidi qallafsan |

| 36-54 | W50 | 350 | Shiidi qallafsan |

| D46 | 325/400 | 320 | Shiidi qallafsan |

| D54 | 270/325 | 270 | Shiidi qallafsan |

| D64 | 230/270 | 230 | Shiidi qallafsan |

| D76 | 200/230 | 200 | Shiidi qallafsan |

4. Cabbirka roodhida qallafsan ee kale

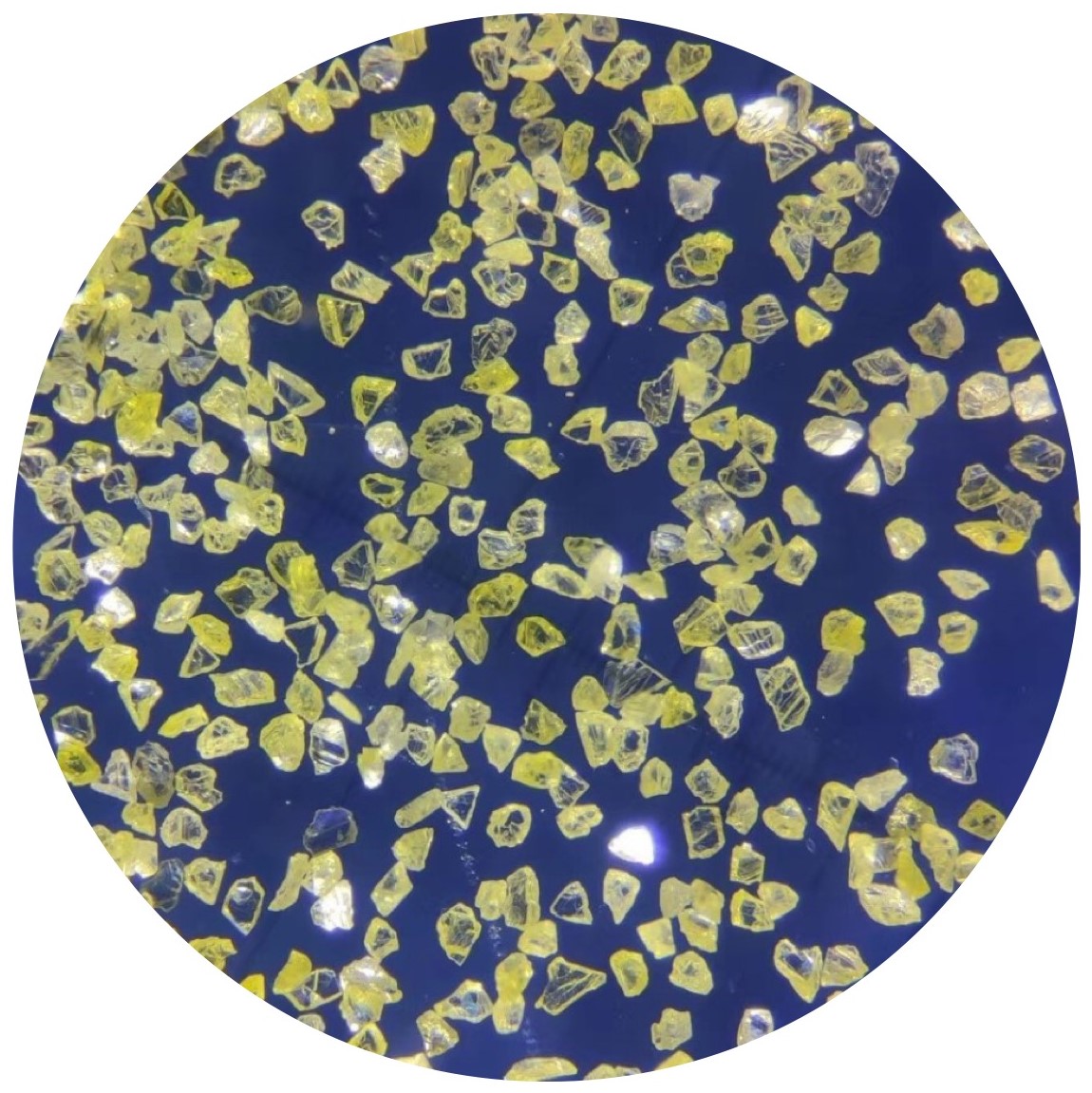

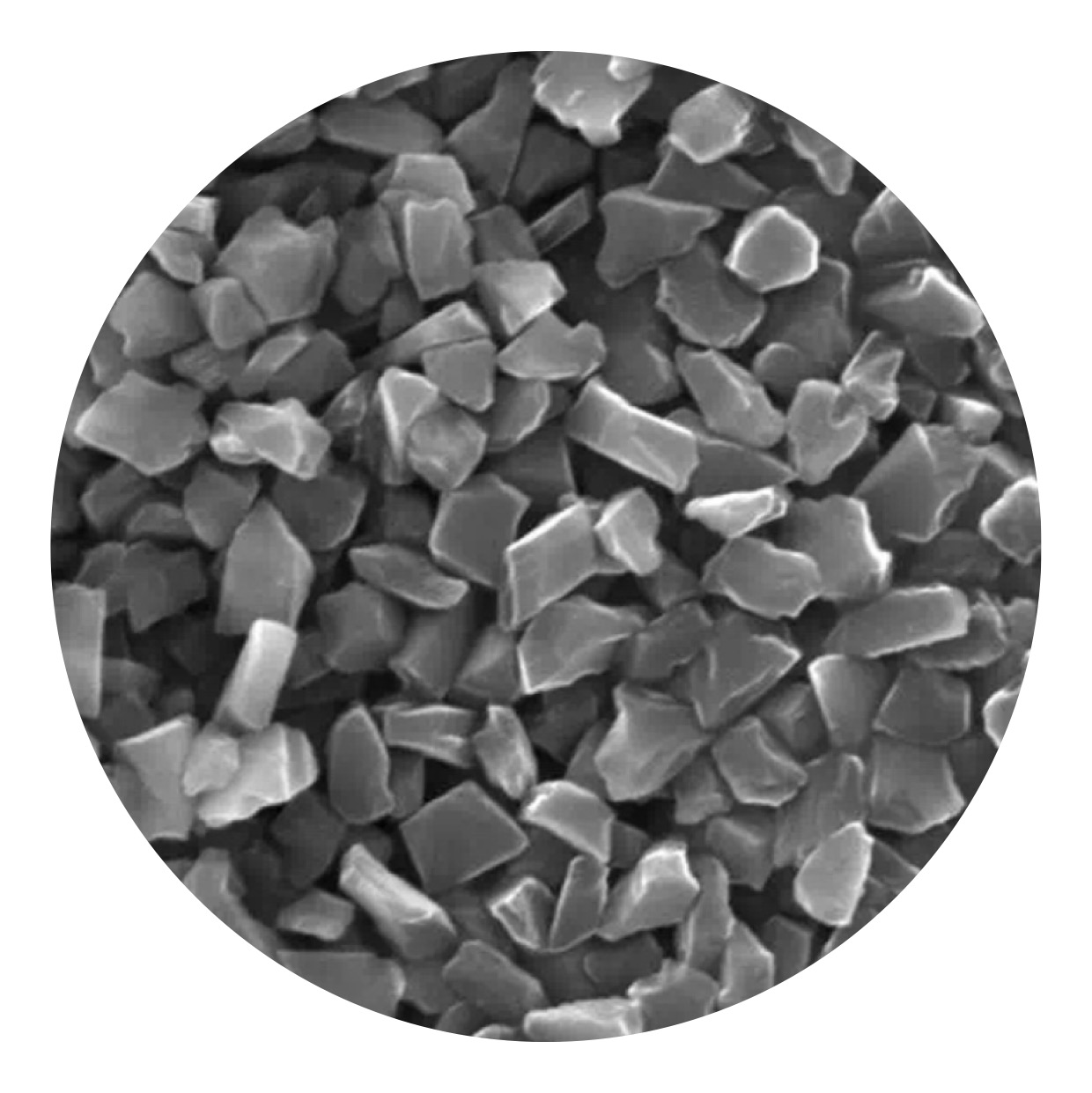

| 50/60-325/400 | Midabka cagaarka ah ee khafiifka ah, qaab aan caadi ahayn oo leh adayg hoose.Si ballaaran loo isticmaalo farsamaynta dhagxaanta, shubka, dhoobada, iwm. | |

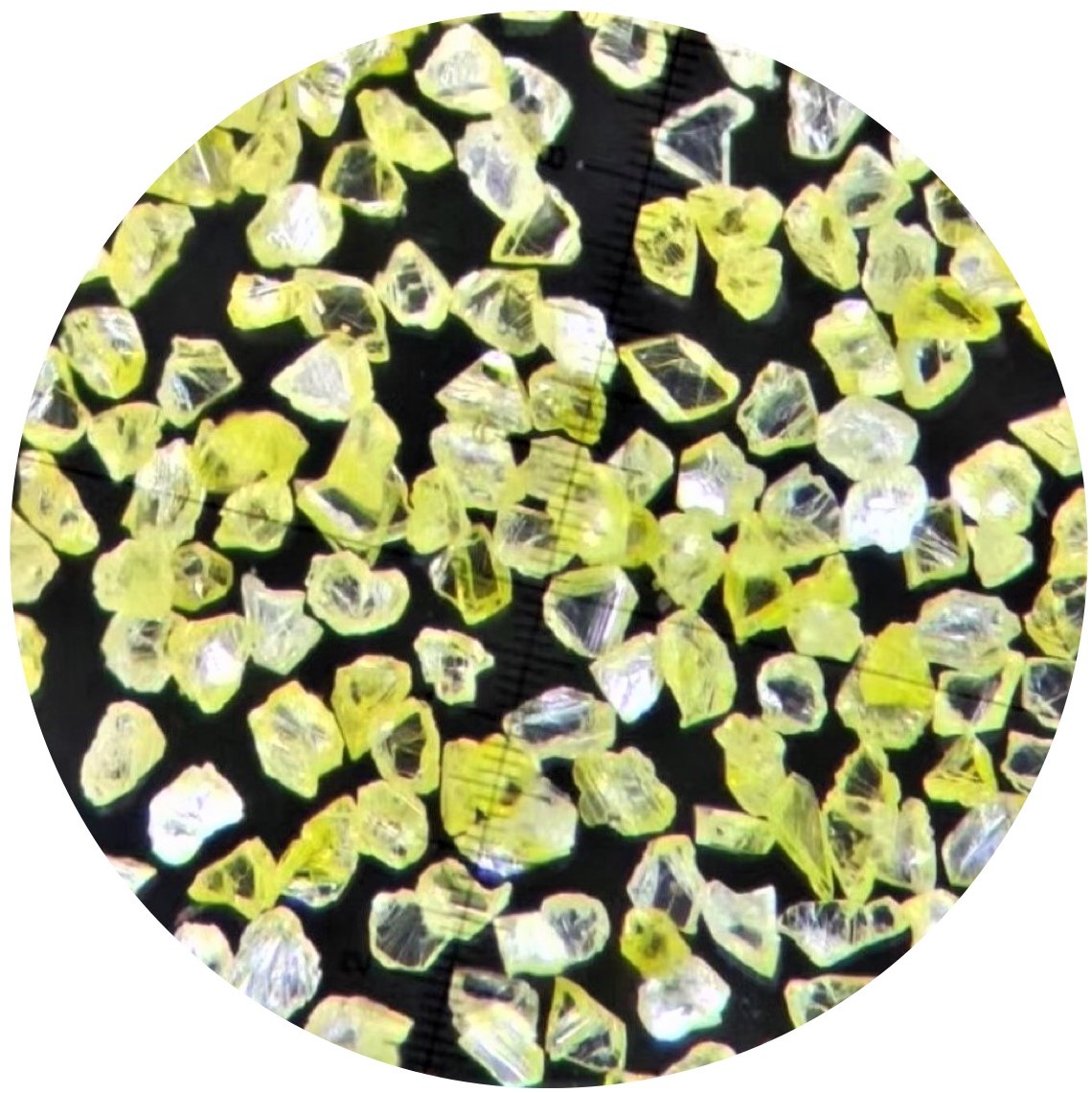

| 30/35-325/400 | Midabka jaalaha ah, qaab aan joogto ahayn oo leh engegan caadiga ah, lagu dabaqay dhoobada isku xidhan, resin bonded iyo dhammaan noocyada electroplating alaabooyinka, loogu talagalay dhagxaanta, daawaha adag, alaabta magnetic, dheeman dabiiciga ah, jawharad. | |

| 30/35-325/400 | Midabka jaalaha ah, adkaanta sare iyo adkaanta.Lagu dabaqay dhoobada curaarta, curaarta resin iyo dhammaan noocyada alaabta korantada, waxay noqon kartaa loo isticmaalo farsamaynta shaqada culus ee karbide, galaas, ceramics, dhagax iyo waxyaabo kale oo aan bir ahayn. |