budada dheemanka ee Nickle Dahaarka leh

Dahaarka Dheeman Nickle Dahaarka lehBudada Dheeman-ka-samaynta

1. Hordhac Dheemman Dahaarka leh

Dheemanka dahaarka leh, wuxuu awood u yeelan karaa xabagta biraha ah ee u dhexeeya Ti iyo matrixka, waxay wanaajisaa ku-xidhka farsamada ee dheemanka matrixka curaarta.Dahabku waxa uu dheemanka ka go'doomi karaa ogsijiinta si looga hortago in dheemanka uu oksaydhisku keeno heerkulka sare ee dheemanka, kaas oo wanaajin kara sifada haynta dheemanka, iyo hagaajinta kulaylka iyo nadiifinta nolosha.

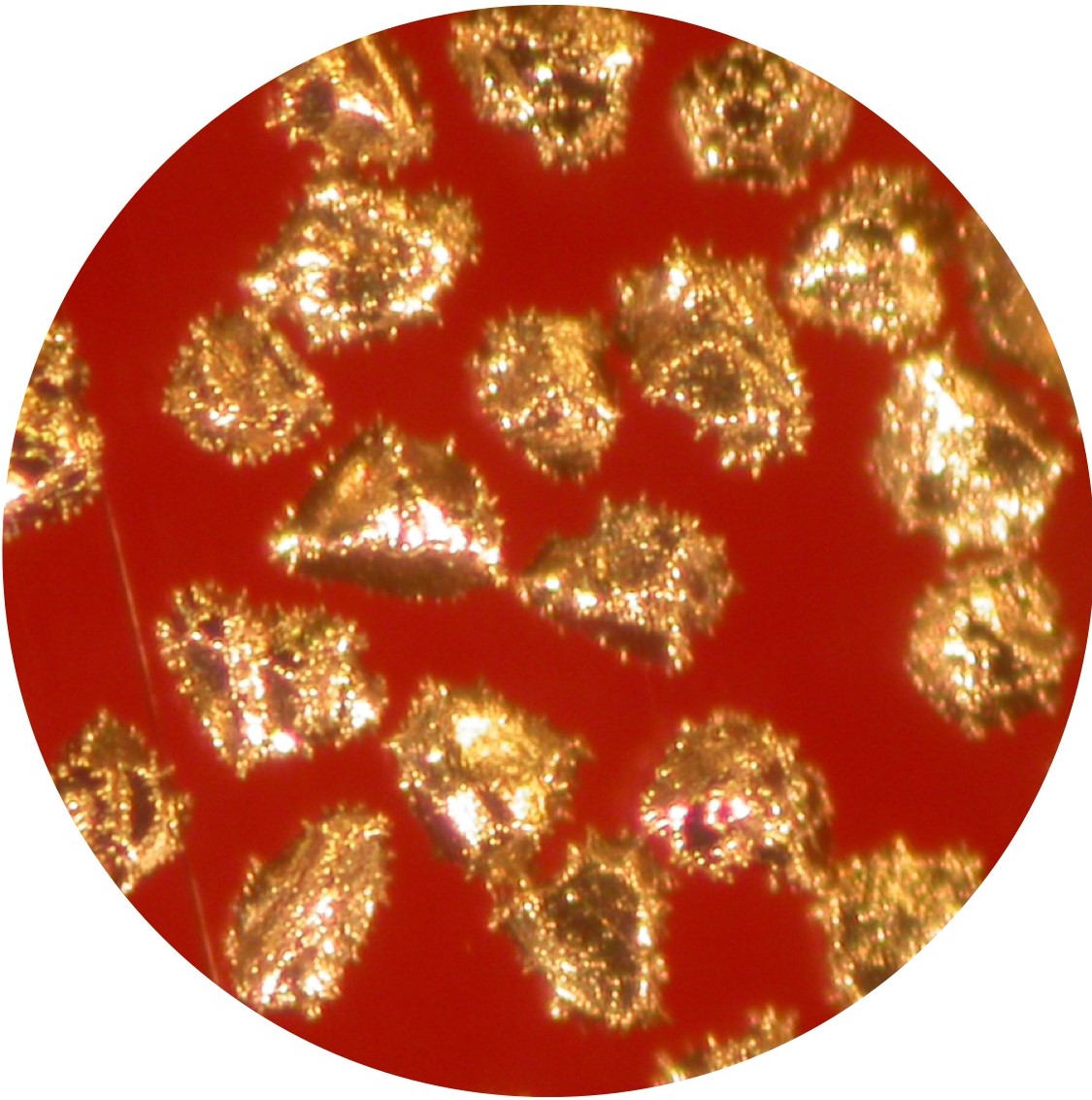

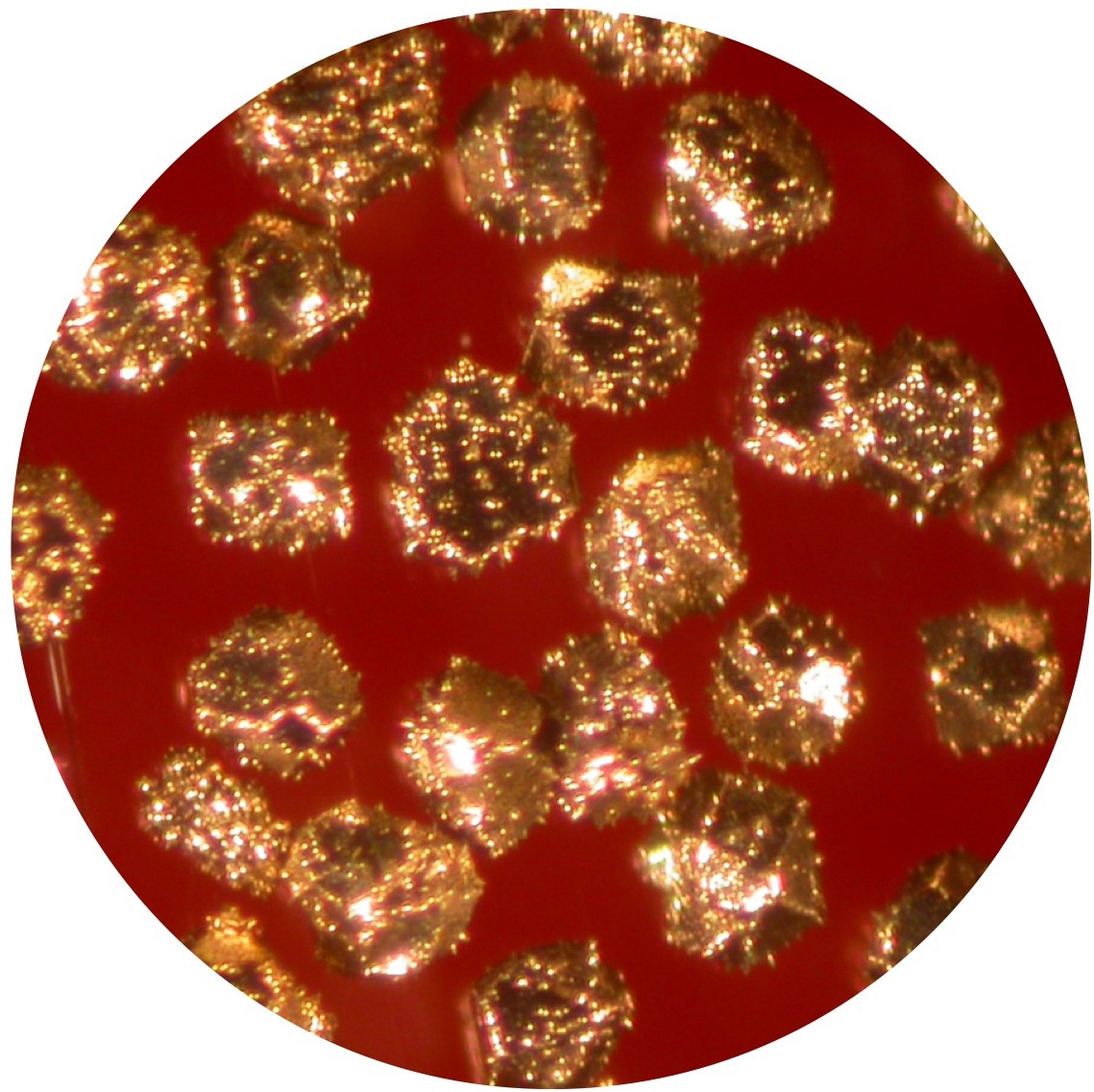

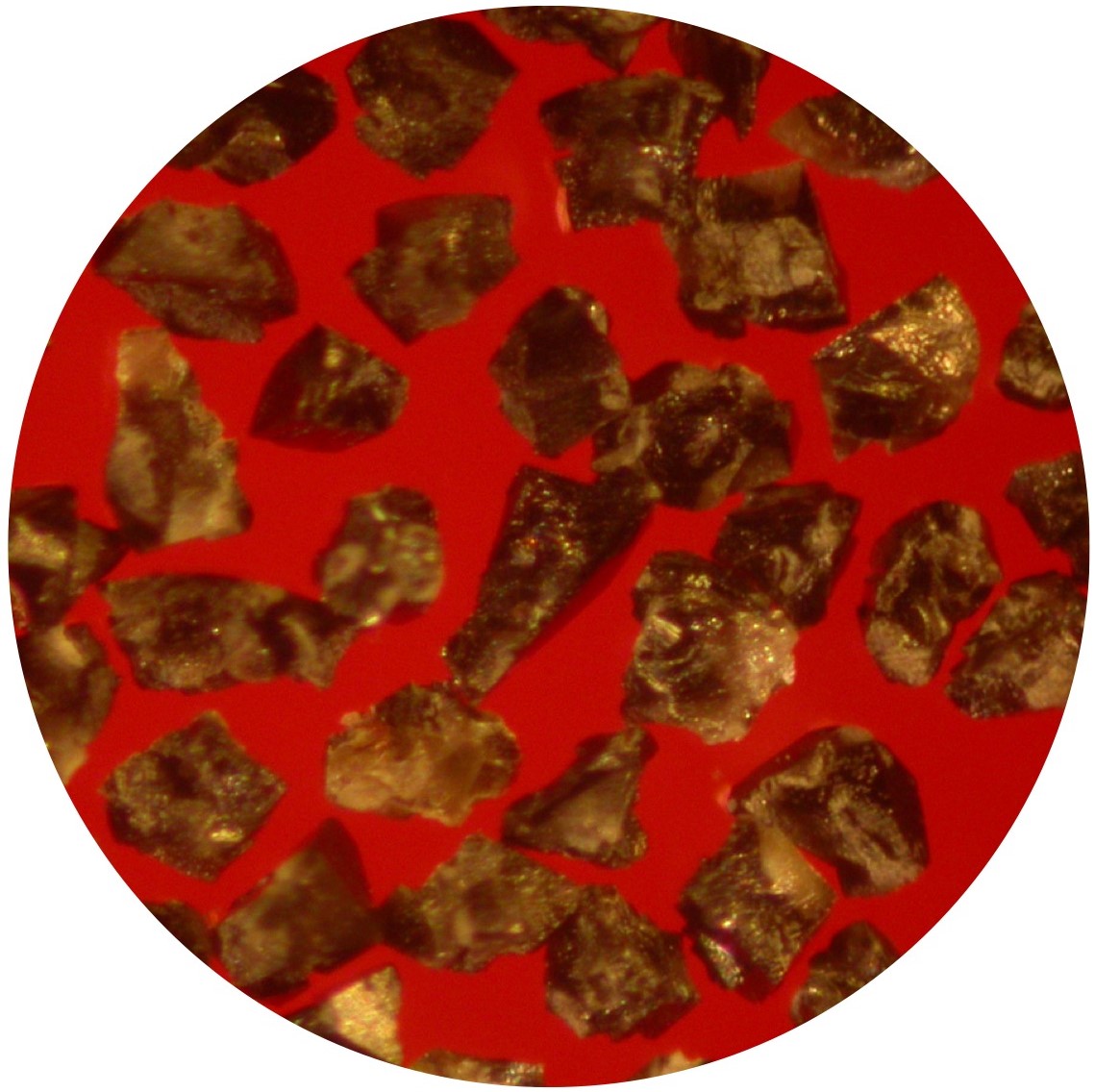

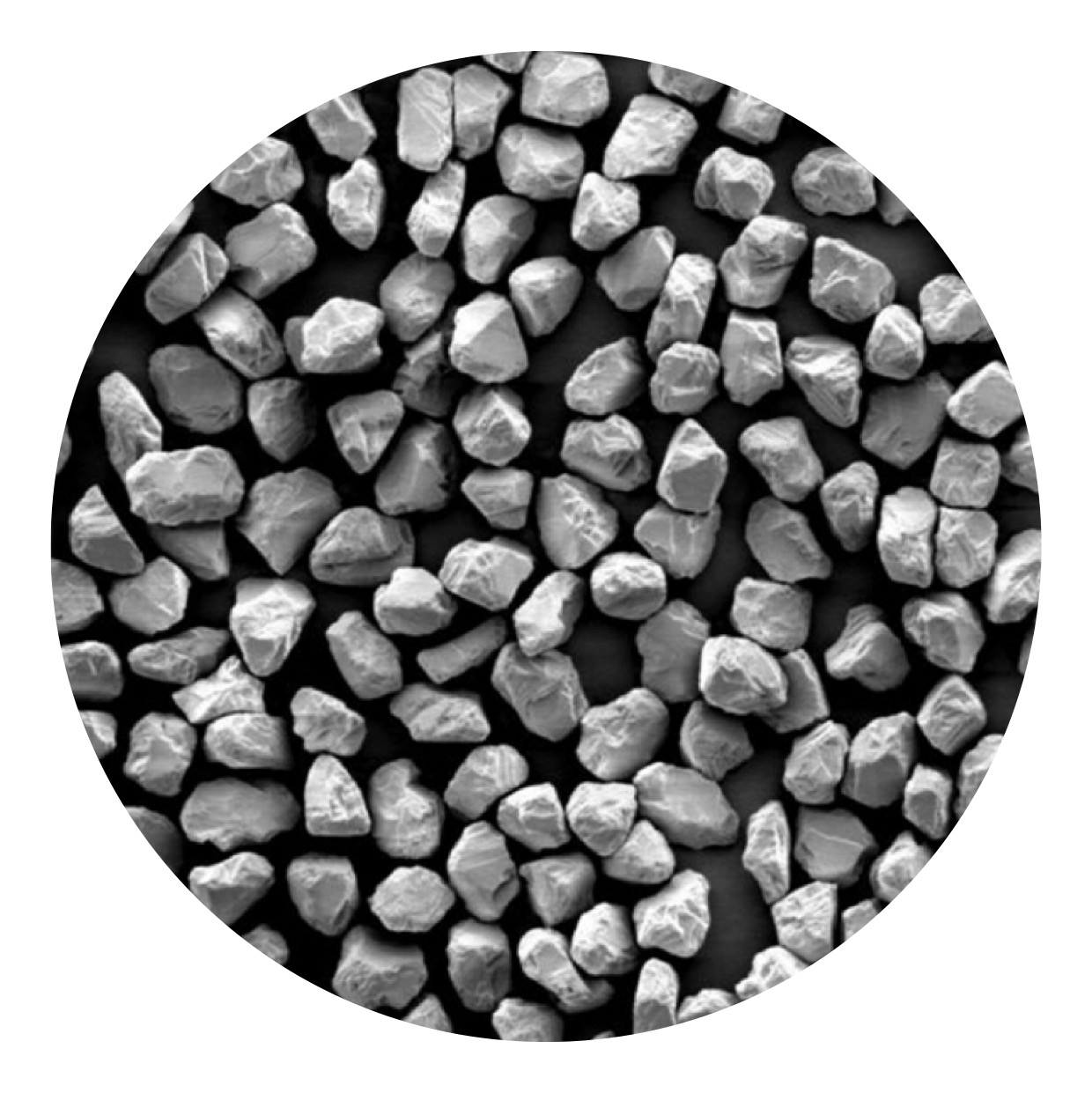

2. Muuqaalka Dheemanka Ni Dahaarka leh

- Dusha qallafsan iyo lafdhabarta, waxay wanaajisaa haynta u dhaxaysa dheemanka iyo dammaanadda, iska ilaali in dheemantu ay goor hore ka baxdo, sidaas darteed, kordhiso nolosha adeegga qalabka dheeman.

- Electrolating iyo dajinta kiimikada;Kordhi miisaanka 30% iyo miisaanka 56%.

- Waxaa lagu talinayaa in la sameeyo qalabka dheemanka resin bond, tusaale ahaan, resin bond dheeman shiidi giraangiraha.

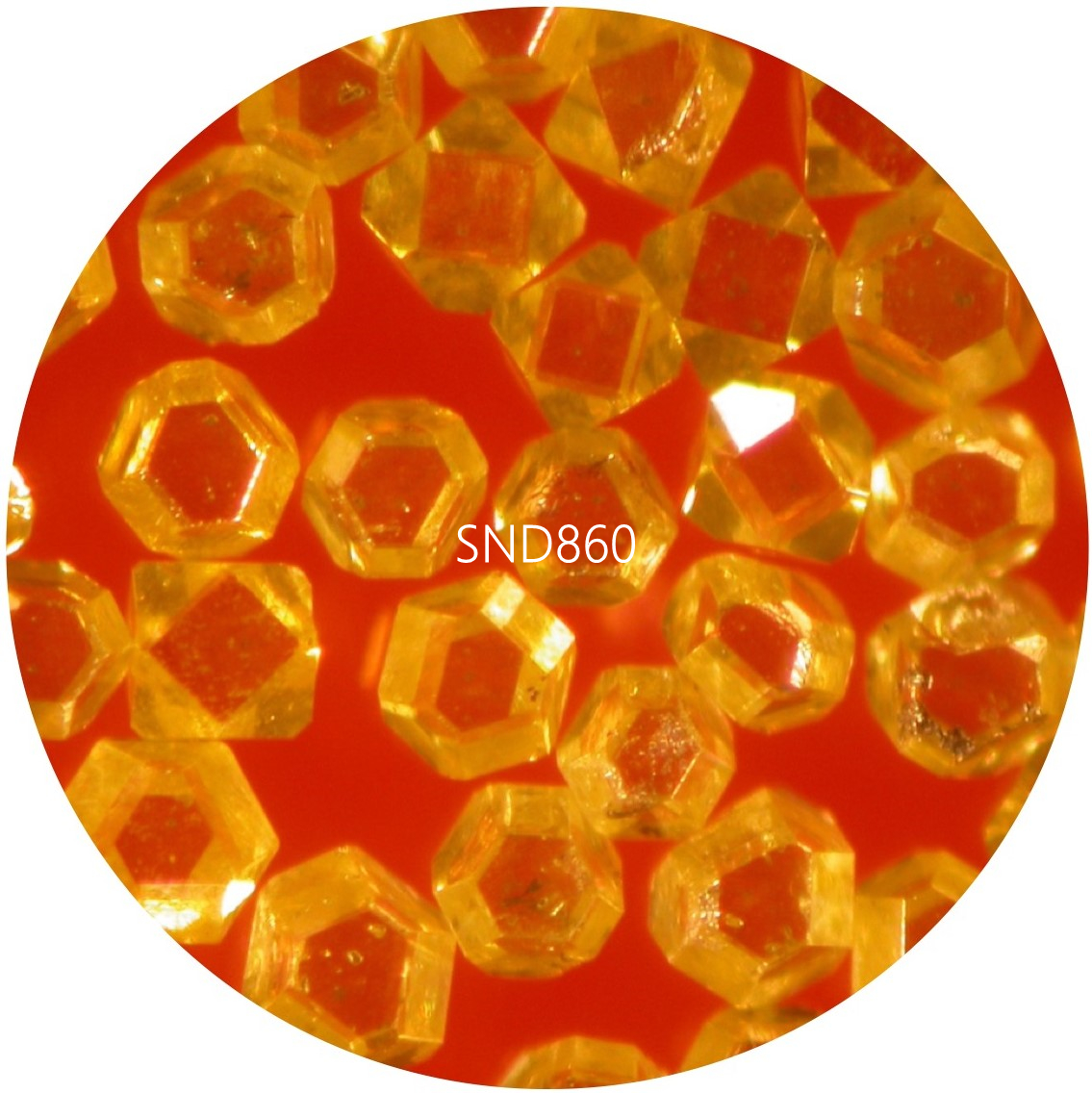

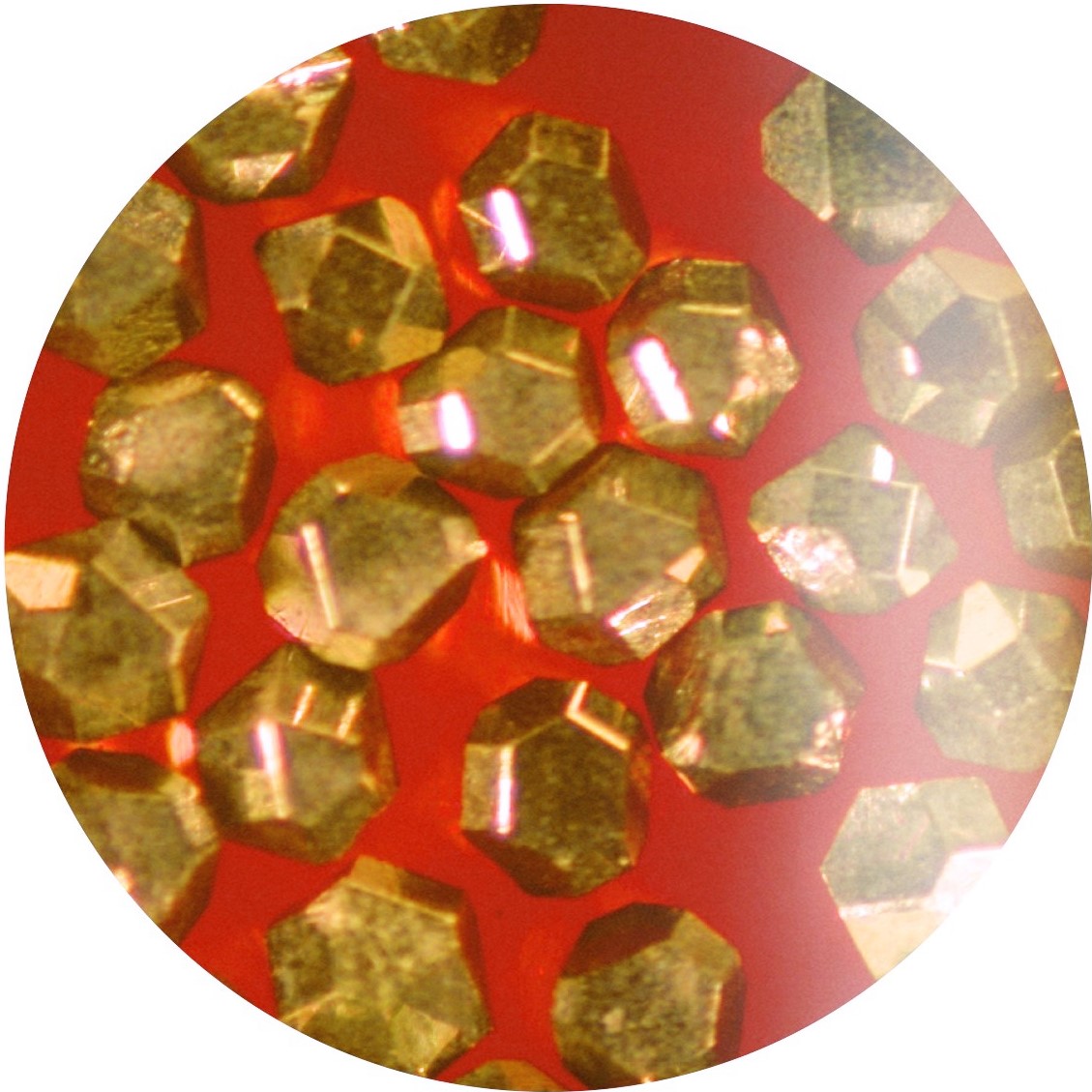

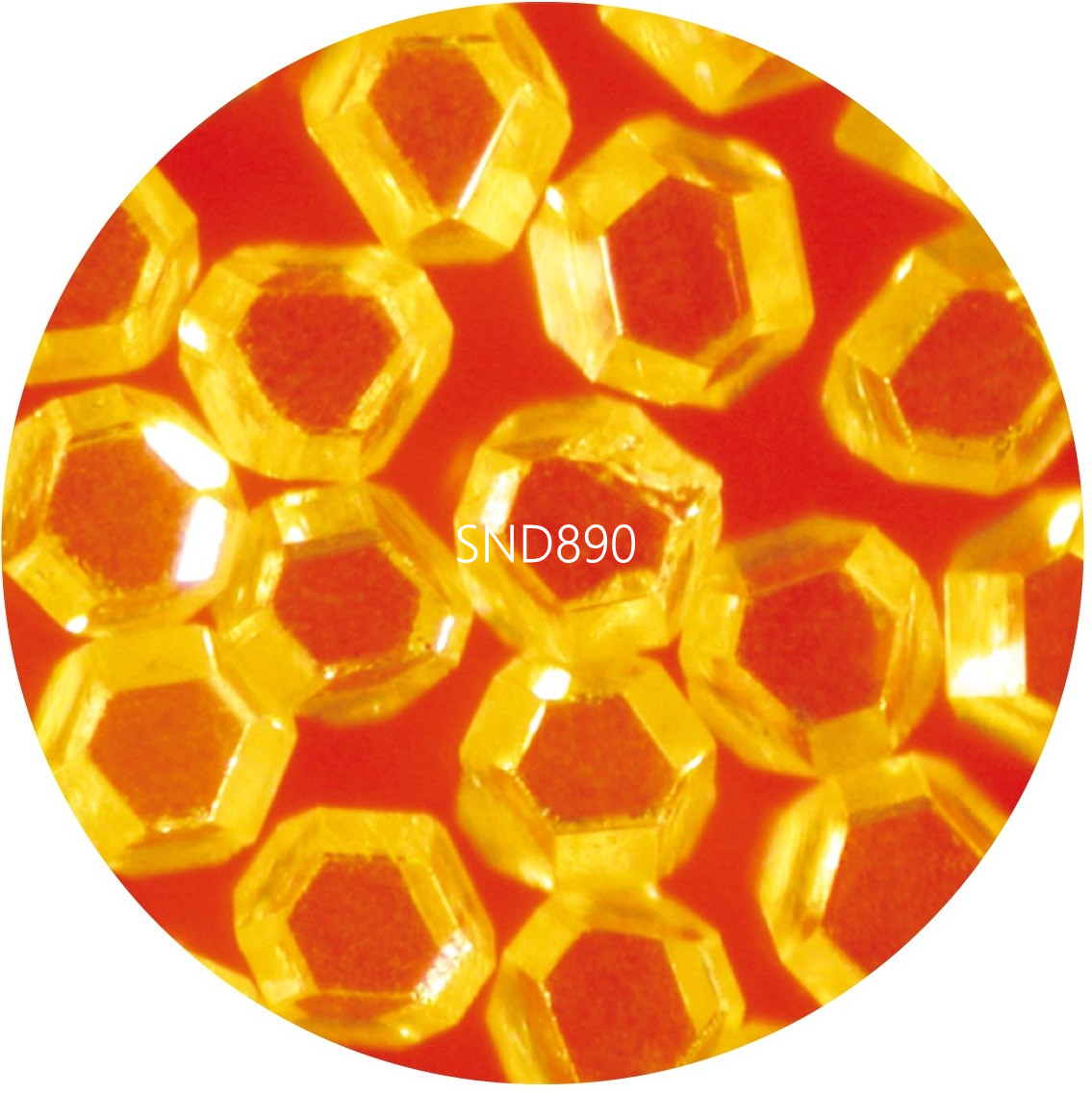

3. Ni Dahaarka Dheemanka Cabbirka

Dheeman aan aragno, dheeman cabbir mesh ah, dheeman jajab ah, dheeman micron inta badan fasalka iyo cabbirka waa la dahaadhay karaa.

| 30/50 | 50/80 | 80/100 | 100/120 | 120/140 | 140/170 | 170/200 | 200/230 | 230/270 | 270/325 | 325/400 | |

| SND-G05 | X | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| SND-G10 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| SND-G15 | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| 80/100 | 100/120 | 120/140 | 140/170 | 170/200 | 200/230 | 230/270 | 270/325 | 325/400 | |

| SND-G20 | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| SND-G30 | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| SND-G40 | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| SND-G60 | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| 20/25 | 25/30 | 30/35 | 35/40 | 40/45 | 45/50 | 50/60 | 60/70 | 70/80 | |

| SND820 | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| SND830 | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| SND840 | x | x | √ | √ | √ | √ | √ | √ | √ |

| SND860 | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| SND870 | x | x | √ | √ | √ | √ | √ | √ | √ |

| SND880 | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| SND890 | √ | √ | √ | √ | √ | √ | x | x | x |

4. Tiknoolajiyada kale ee Dahaarka Birta

| Nooca curaarta | Dahaarka lagu taliyay |

| Curinta birta | Titanium, Tungsten, Molybdenum, Chromium, Zirconium |

| Xaraashka xabagta | Nikkel, Copper, Aluminum, Birta-Nickel Alloy, Cu-Tin Alloy |

| Dabaajiga vitrified | Tungsten Carbide, Titanium Carbide, Kaarboon-Titanium Nitride, Aluminium Titanium Nitride. |